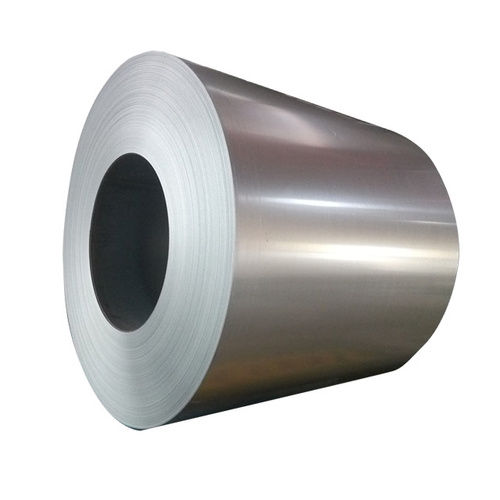

PPGI PREPAINTED GALVANISED COIL

PPGI PREPAINTED GALVANISED COIL Specification

- Surface Treatment

- Prepainted / Colour Coated

- Material

- Galvanized Steel

- Technique

- Cold Rolled

- Grade

- ASTM A653 / JIS G3312 / IS 513

- Coil Thickness

- 0.12 mm - 1.2 mm

- Coil Weight

- 3 - 10 Metric Tons

- Coil Length

- Customized as per requirement

- Hardness

- Full Hard / Soft

- Application

- Roofing, Cladding, Construction, Automotive, Appliances

- Formability

- Excellent

- Zinc Coating

- Z80 to Z275 g/m²

- Paint Coating

- 15-25 microns (Top), 5-10 microns (Back)

- Tolerance

- Thickness ±0.02 mm

- Standard

- IS / ASTM / JIS / EN

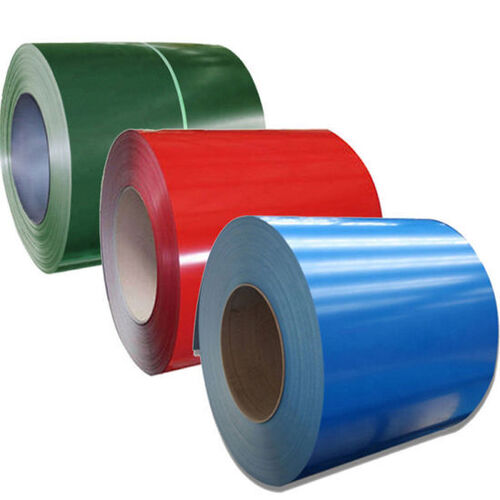

- Colour

- Multiple RAL shades available

- Edge Condition

- Mill Edge / Slit Edge

- Packing Type

- Standard Export Seaworthy Packing

- Width

- 600 mm - 1500 mm

- Finish

- Matte / Glossy / Textured

- Corrosion Resistance

- High

- Inner Diameter

- 508 mm / 610 mm

PPGI PREPAINTED GALVANISED COIL Trade Information

- Minimum Order Quantity

- 5 Tons

- Supply Ability

- 50 Tons Per Day

- Delivery Time

- 4 Days

- Sample Policy

- Contact us for information regarding our sample policy

- Main Domestic Market

- West India

About PPGI PREPAINTED GALVANISED COIL

Indian Steel Empire is a renowned name that deals in the supplying and exporting of premium quality PPGI,PRE-PAINTED GALVANISED COIL that is made up by using best in class alloyed steel that provides high tensile strength and impact resistance. It is provided with a rust resistant paint coat that makes it suitable for corrosive as well as non-corrosive applications. The offered PPGI, PRE-PAINTED GALVANISED COIL comes in various sizes as per the order placed by our customers.

Versatile Applications

PPGI Prepainted Galvanised Coils are widely adopted across sectors such as construction, automotive, roofing, cladding, and appliances. Their adaptability to multiple environments makes them a preferred choice for architects and engineers seeking longevity and vibrant finishes.

Superior Protection and Finish

With high zinc coating (Z80-Z275 g/m2) and a robust paint layer on both sides, these coils provide excellent corrosion resistance and are available in diverse finishes including matte, glossy, and textured. Customers can choose from various RAL shades to match project requirements.

Compliance and Customization

Manufactured as per international standards (IS, ASTM, JIS, EN) and available in customizable coil lengths and thickness tolerances, these coils meet global quality benchmarks. Edge conditions (mill or slit) and coil diameters cater to specific operational needs and logistics.

FAQ's of PPGI PREPAINTED GALVANISED COIL:

Q: How is PPGI Prepainted Galvanised Coil manufactured?

A: These coils start as galvanized steel, which is cold-rolled and then coated with a layer of zinc (Z80 to Z275 g/m2). After galvanizing, both sides are coated with paint (15-25 microns top, 5-10 microns back) in controlled lines, ensuring durability and uniformity before being finished in various textures or gloss levels.Q: What benefits does PPGI Prepainted Galvanised Coil offer for construction projects?

A: PPGI coils offer high corrosion resistance, excellent formability, a wide selection of finishes and colors, and compliance with international standards, making them ideal for long-lasting, visually appealing roofing and cladding solutions in diverse construction environments.Q: When should I use matte, glossy, or textured finishes?

A: Matte finishes are used for a subdued appearance with minimal reflection, glossy finishes enhance brightness and are easy to clean, while textured finishes provide slip resistance and unique aesthetics. The choice depends on functional and visual requirements of the project.Q: Where can PPGI coils be applied besides construction?

A: Apart from construction, PPGI coils are widely used in the automotive sector for body components, in home appliances for panels, and in manufacturing prefabricated structures, showcasing their versatility and robustness.Q: What is the process for ordering customized coil length or color?

A: Customers should specify the required coil length, color (from multiple RAL options), finish, and technical requirements when placing an order. The manufacturer will customize the product accordingly, ensuring tailored solutions for each project.Q: How does the zinc and paint coating enhance corrosion resistance?

A: The zinc layer acts as a barrier protecting the base steel, while the paint coating further prevents moisture and chemicals from reaching the metal surface, providing double assurance of long-term corrosion resistance.Q: What packing and shipment standards are followed for exports?

A: PPGI coils are packed using standard export seaworthy packing materials to prevent damage during transit. Options for inner diameter (508 mm / 610 mm) and coil weight (3-10 MT) offer logistical flexibility for international shipping.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

More Products in Pre Painted Coated Coil Category

Color Coated Coils

Price 75000.00 INR / Ton

Minimum Order Quantity : 1 Ton

Surface Treatment : Painted

Application : CONSTRUCTION

Coil Weight : 5000 5500 Kilograms (kg)

Material : Steel

Prepainted Galvalume Coil

Price 94000.00 INR / Ton

Minimum Order Quantity : 1 Ton

Surface Treatment : Galvanized

Application : Automobile Industry, Sheet Metal Manufacturers, Pipes & Tubes

Coil Weight : 5000 5500 Kilograms (kg)

Material : Steel

|

INDIAN STEEL EMPIRE

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |